Performance table

Features

Structure

Machine Equipment

Optional Features

Performance table

| Operational pressure (bar) | Flow rate from (l/h) | Flow rate to (l/h) |

| 100 | 6.200 | 11.500 |

|---|---|---|

| 130 | 6.200 | 10.000 |

| 150 | 6.200 | 9.400 |

| 180 | 5.200 | 7.500 |

| 200 | 4.700 | 7.000 |

| 230 | 4.200 | 6.000 |

| 250 | 3.700 | 5.500 |

| 300 | 3.200 | 4.700 |

Features

- Compression Head guaranteed for 5 YEARS against breakage, made from a single block of special type stainless steel, forged and ultrasonically tested.

- Valve Groups housed in individual blocks of special AISI 316 stainless steel, each individually inspectable.

- Pumping pistons with rear cooling chamber, optimal alignment with double guide, special coating (standard) over their entire length in “Diamond Like Carbon”.

- Interchangeable Valve Seats and Hemispherical Valves designed to handle a very wide range of products.

- Homogenizing valves of high efficiency thanks to a design focused on maximum stability/alignment of the moving element (Impact Head) and the use of a hydraulic push group to avoid any possible onset of vibrations during operation.

- Safety valve in sanitary design, operating with a pre-loaded spring with interchangeable shutter and seat.

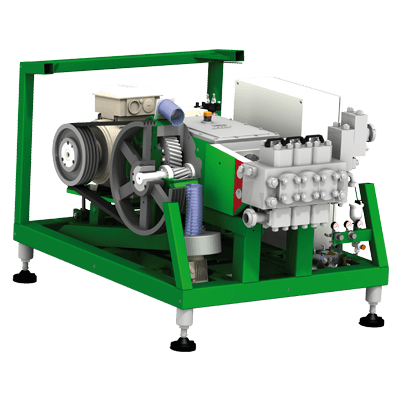

Structure

- Pump Body made of high-quality cast iron with high resistance and thick walls, developed to withstand heavy loads and cancel operational vibrations.

- Crankshaft made from solid special steel, thermally treated with super-finish of the goose necks and complete nitriding; it is supported by high-performance roller bearings (bushings used exclusively on the goose necks).

- Transmission of movement with double reduction stage: trapezoidal belts/pulleys plus a parallel-axis reducer of leading brand (no cooling water required).

- Forced lubrication with oil level window located on the front of the machine, irregular pressure alarm, intensive filtering of any impurities. Furthermore, for optimal balance/heat dissipation, all parts dedicated to motion transmission are oil bathed.

- Alternating current motor, of leading brand and 4-pole standard.

- Frame made with heavy section square steel, powder coated; this solid structure is fully clad in stainless steel panels with a satin finish.

Machine Equipment

- Set of first-use spare parts (complete set of Seals, set of Valve group Springs, Safety Valve set).

- Tools for regular maintenance.

- Pump Body lubrication oil.

- User-Maintenance Manual (2 copies + CD ROM).

Optional Features

- Double stage of servo-assisted homogenization (oleopneumatic group).

- Digital pressure transducers and analogue pressure gauges with 4-20 mA output signals.

- Fixed Flow (internal electrical panel of the machine).

- Variable Flow (external stainless steel electrical panel of the machine).

- Aseptic Version through the use of sterile condensation barriers produced by a dedicated integrated system.

- Compensation Lungs at Product Inlet/Outlet, also specific for aseptic productions.

- Product inlet pressure gauge with alarm contact, with timed management of the disconnection-connection of homogenizing valves.

- Semi-automatic/automatic control of homogenization pressures.

*Non-binding and subject to change without notice technical specifications.

Download

ACCESSORIESRemote Homogenizing

Remote Homogenizing

Valve

Do you have a single-stage homogenizer and want to convert it into a two-stage homogenizer easily, quickly and inexpensively?

Thanks to the Remote Homogenizing Valve (VOD), which consists of a complete homogenizing chamber that can be operated independently of the existing homogenizer, it is possible to transform the single-stage homogenizer into a two-stage homogenizer.

This is made possible by a Remote Homogenizing Valve equipped with a single pressure gauge for reading the homogenizing pressure.